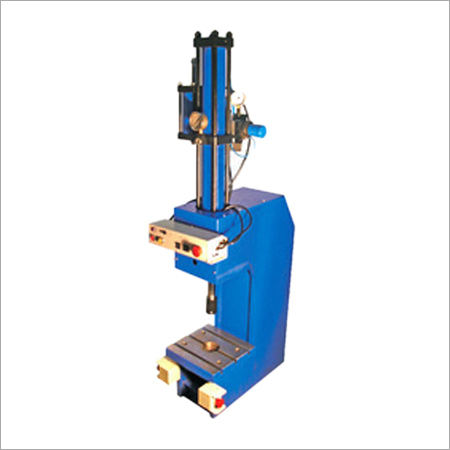

About Hydro Pneumatic Stamping Press

We have emerged as a leading manufacturer, exporter, supplier and trader of Hydro Pneumatic Stamping Press. Made form finest grade raw materials like steel, iron and alloy, this pneumatic tool has wide usage in punching, embossing, straightening and stamping works. The necessary technical specifications of our Hydro Pneumatic Stamping Press include

Type of Presses : | Capacity (Tone) | Strocke (mm) | Power Strocke (mm) |

Hydro Pneumatic Cylinder | 2,4,8,15,30 | 50,75,100,150 | 3,6,12,24 |

2 Piller Presses | 2,4,8,15,30 | 50,75,100,150 | 3,6,12,24 |

4 Piller Presses | 2,4,8,15,30 | 50,75,100,150 | 3,6,12,24 |

C Frame Presses | 2,4,8,15,30 | 50,75,100,150 | 3,6,12,24 |

Compact C Frame Presses | 2,4,8 | 50,75,100,150 | 3,6,12,24 |

Robust and Reliable ConstructionFabricated from heavy-duty mild steel, the Hydro Pneumatic Stamping Press is designed to withstand demanding industrial environments while offering a long service life. The powder-coated finish provides optimal resistance to corrosion, making it a sturdy asset for any workshop.

Advanced Controls and FlexibilityEquipped with a digital control panel, PLC system, and options for both manual and automatic operation, this press offers precise control over stamping and forming processes. Its customizable nominal force and adjustable stroke make it adaptable to a variety of tasks and production requirements.

Safety as a PriorityOperator safety is ensured through robust safety features, including an emergency stop button and a two-hand push button operation system. Low noise emission and a secure, well-structured frame further enhance safe and comfortable working conditions.

FAQs of Hydro Pneumatic Stamping Press:

Q: How does the stroke length adjustment benefit my production process?

A: The stroke length can be adjusted from 100 mm to 250 mm, allowing you to tailor the press to various workpiece heights and stamping depths. This customization supports a wide range of applications and materials, increasing process efficiency and product quality.

Q: What safety mechanisms are integrated into this stamping press?

A: Safety is prioritized with features such as an emergency stop button, two-hand push buttons to prevent accidental engagement, and a secure digital control panel. These features ensure both operator protection and smooth workflow.

Q: When is it best to use the manual versus automatic operating mode?

A: Manual mode is ideal for setup, prototyping, or operations requiring greater oversight, while automatic mode is suited for high-volume or repetitive production, offering enhanced efficiency and consistency.

Q: Where is this hydro pneumatic stamping press most commonly employed?

A: This press is widely utilized in manufacturing environments such as automotive, appliance, and metalworking industries, especially where stamping, punching, forming, or embossing are required.

Q: What are the benefits of having a PLC system on this machine?

A: The PLC system enables precise control and programmability, simplifies changes to process parameters, and aids in troubleshooting, ultimately boosting productivity and reducing downtime.

Q: How does the oil tank capacity and power system support continuous operation?

A: A 30-liter oil tank ensures consistent hydraulic pressure and cooling, while the 3 HP hydraulic/electric motor provides reliable power for sustained, efficient operation even during intensive production cycles.